Leather

Listed here are items designed and crafted entirely by hand from beginning to end

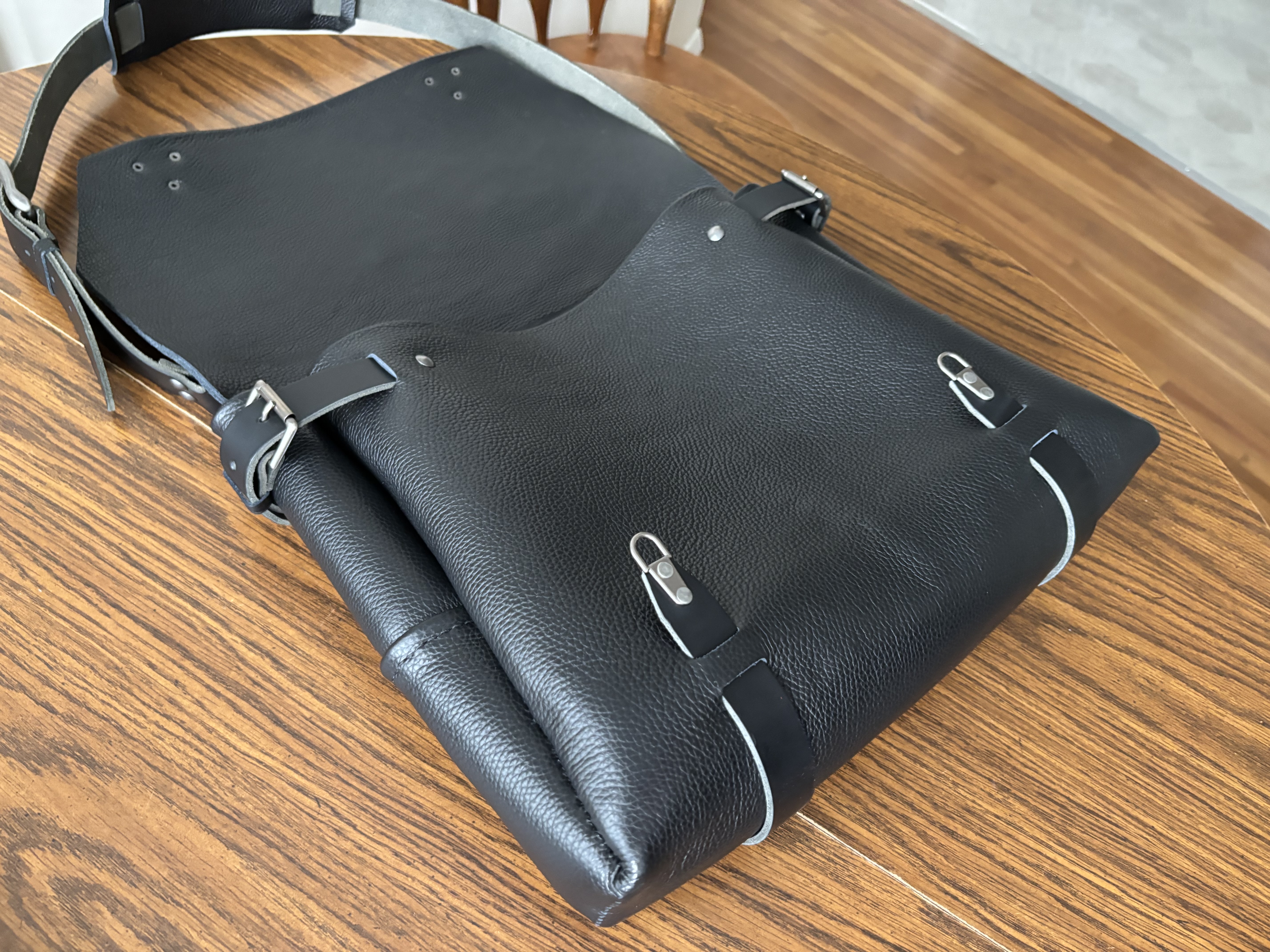

Messenger

Bucket Tote

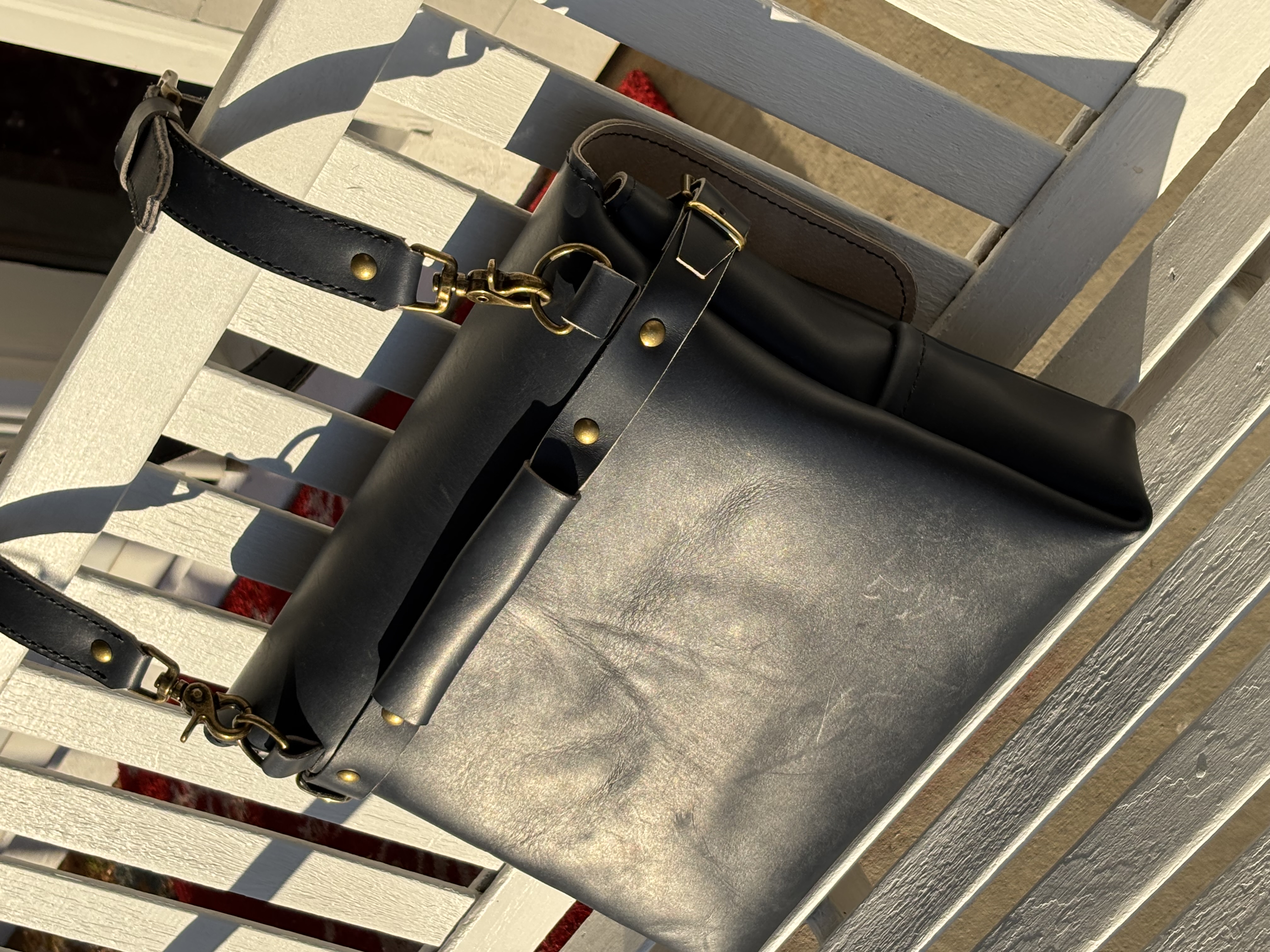

Vertical Messenger

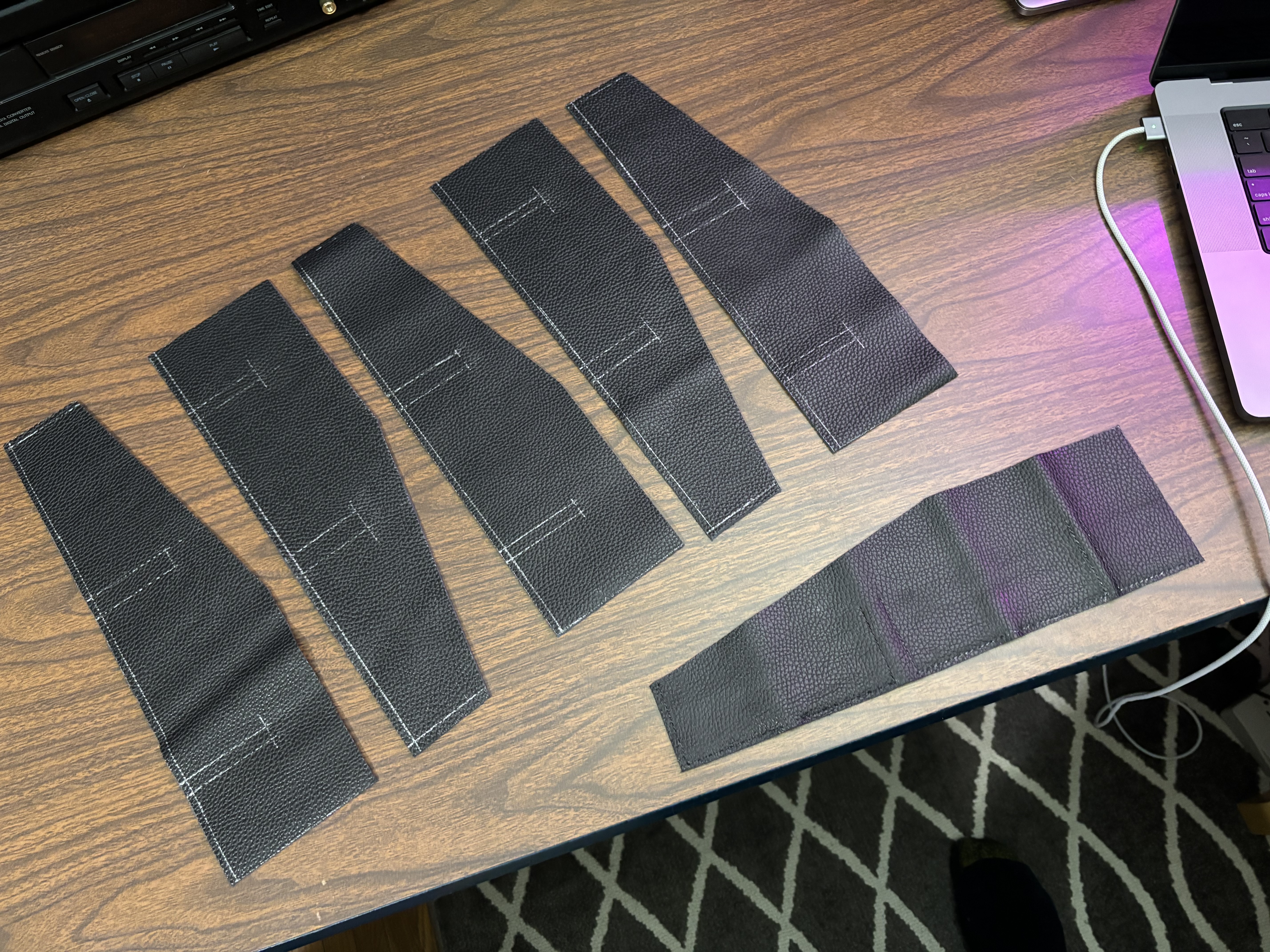

Belts

Wrap Wallet

Card Carrier

Coin Carrier

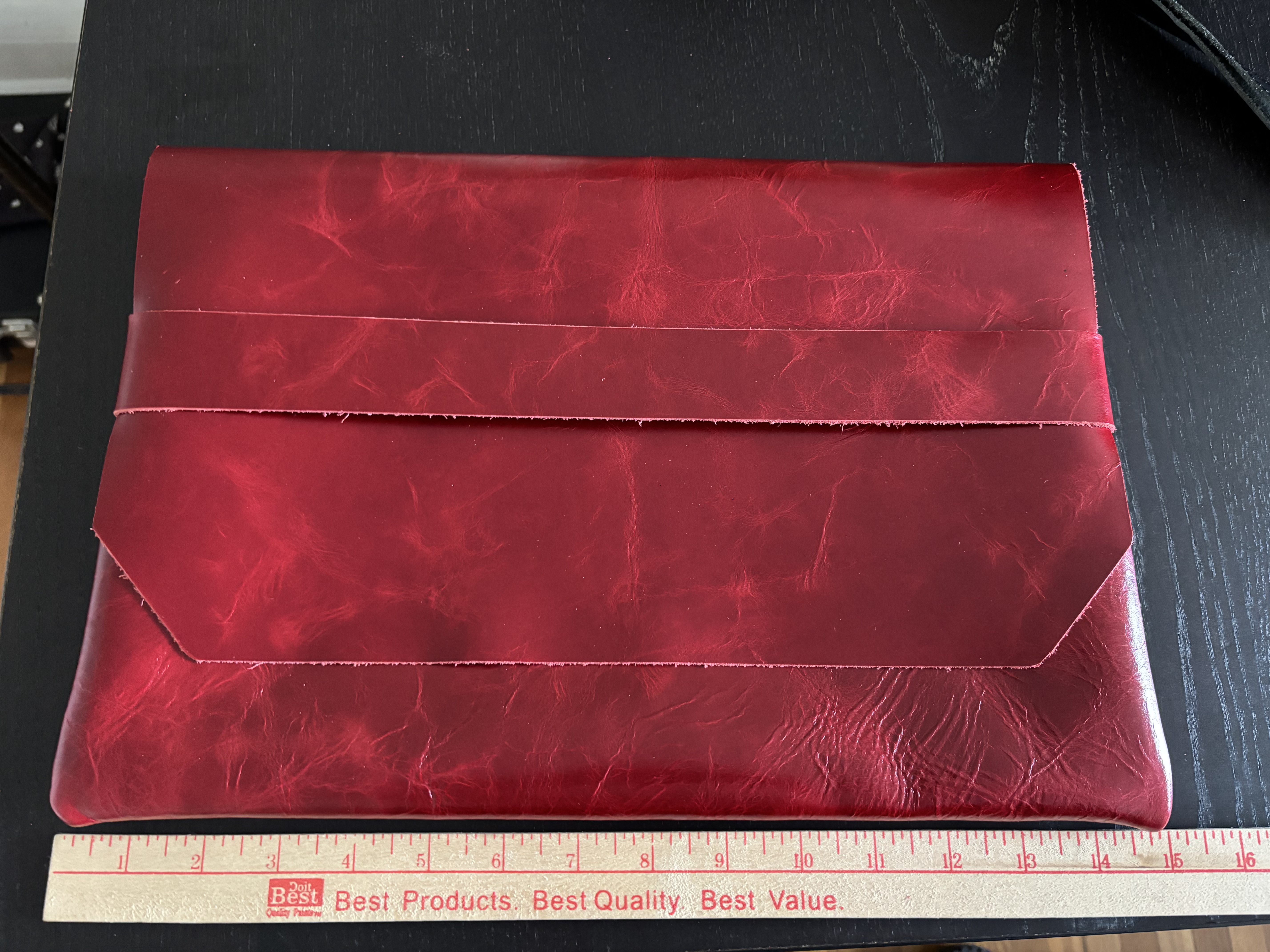

Laptop Sleeve

Misc.